Multifunctional composite binder for iron ore oxide pellets

To improve the balling performance of iron concentrate, reduce the ratio of use, reduce the introduction of gangue elements, and reduce the energy consumption of blast furnace.

Key words:

Key words:

Bentonite mining, cat litter

Classification:

New steel pellet binder

Product Description

1. The importance of developing oxidized pellets

Uniform particle size, high strength, high iron grade and excellent metallurgical properties are conducive to improving the yield of molten iron and reducing the coke ratio; energy consumption and carbon emissions of the pellet method are reduced by more than 50%, and the flue gas pollutant emission load is only about 20% of that of sintering;

Blast furnace into the furnace ratio: Europe and the United States/North America 80%-90%, even 100; China less than 15%;

Vigorously developing pellet production is of great significance to promote energy conservation, emission reduction and green development of the iron and steel industry.

2. The necessity of the development of new binders

Resource depletion: decreased iron grade, SiO2, Al2O3, P, S, alkali metal, crystal water content increased;

The proportion of high-quality iron concentrate supply is gradually decreasing: the utilization of poor, fine and mixed iron ore;

Granularity: fine grinding and deep separation of lean ore, fine grained concentrate at the same time surface adhesion flotation agent, hydrophilic performance decreased;

Many varieties and complicated properties: mirror iron ore, sulfuric acid slag, laterite nickel ore, high S iron concentrate, goethite, boron-containing iron concentrate, vanadium-titanium magnetite, chromite, high-magnesium magnetite concentrate, Steel mill solid waste and other raw materials with complex compositions and properties are used to prepare pellets.

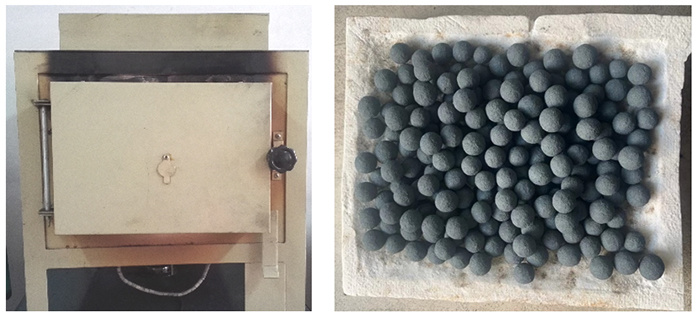

Experiment of Balling with Different Binder

| Type of binder | Proportion/% | Drop strength/time/0.5m | Compressive strength/N/unit | Bursting temperature/℃ | Yield/% |

| Domestic common bentonite | 3.0 | 3.2 | 10.1 | 560 | 92 |

| Company-produced bentonite | 2.6 | 3.5 | 10.9 | 570 | 95 |

| Foreign mainstream bentonite | 2.0 | 4.2 | 11.8 | 580 | 100 |

| composite binder | 1.6 | 5.0 | 12.1 | 580 | 100 |

The composite binder has better balling performance than bentonite at home and abroad, especially for the coarse-grained, low-specific surface area of iron concentrate ball gain effect is more obvious.

The composite binder has better balling performance than bentonite at home and abroad, especially for the coarse-grained, low-specific surface area of iron concentrate ball gain effect is more obvious.

Properties of calcined pellets with different binders

| Type of binder | Compressive strength/N/unit | Low temperature reduction powder RDI +3.15 / % | Low temperature reduction pulverization RDI-0.5 / % | Reduction expansion/% |

| Domestic common bentonite | 2320 | 97.10 | 1.64 | 11.3 |

| Company-produced bentonite | 2480 | 97.43 | 1.57 | 10.2 |

| Foreign mainstream bentonite | 2510 | 98.89 | 1.40 | 8.1 |

| composite binder | 2425 | 98.21 | 1.45 | 8.9 |

The pellets after adding the composite binder also have good roasting and metallurgical properties.

economic benefit of pellet

| Type of binder | Proportion/% | Sio2Content/% | Increase Sio2Content/% | Unit Price/Yuan/t | Cost/yuan/t |

| Domestic common bentonite | 3.0 | 54.56 | 1.74 | 800 | 24.0 |

| Company-produced bentonite | 2.6 | 58.80 | 1.53 | 950 | 24.7 |

| Foreign mainstream bentonite | 2.0 | 46.80 | 0.93 | 1300 | 26.0 |

| composite binder | 1.6 | 49.98 | 0.80 | 1200 | 19.2 |

The cost of binder is reduced by about 5 yuan/t, and the cost is saved by 10 million yuan per year for a pellet field of 2 million tons per year.

| Type of binder | Proportion/% | Increase Sio2Content/% | Balling binder cost/yuan/t | Lost Silicon Freight/Yuan/t | Smelting loss benefit of silicon-enhanced blast furnace/yuan/t | Comprehensive benefit/yuan/t |

| Domestic common bentonite | 3.0 | 1.74 |

24.0 |

2.63 |

28.38 |

55.01 |

| Company-produced bentonite | 2.6 | 1.53 | 24.7 | 2.31 | 24.95 | 51.96 |

| Foreign mainstream bentonite | 2.0 | 0.93 |

26.0 |

1.40 | 15.17 | 42.57 |

| composite binder | 1.6 | 0.80 | 19.2 | 1.21 | 13.05 | 33.46 |

The use of composite binder to reduce the overall cost of about 10-22 yuan, to 2 million tons per year of the pellet plant pellets directly blast furnace smelting, cost savings of about 2000-44 million yuan.

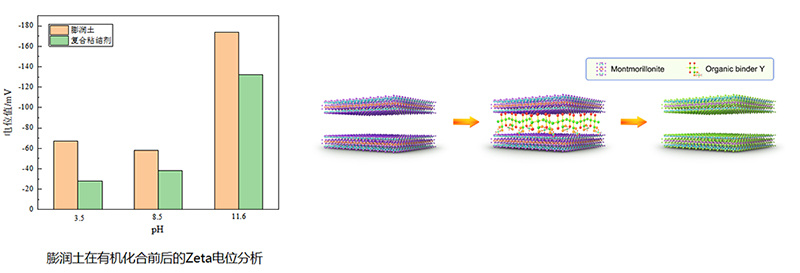

| Sample | Glial value/%·(3g)-1 | Expansion ratio/ml · g-1 | Water absorption (2h)/% | Volume of blue absorption/g ·(100g)-1 | Montmorillonite content/% | PH |

| Bentonite | 100 | 25.20 | 308 | 37.71 | 85.32 | 8.9 |

| composite binder | 100 | 42.43 | 421 | 45.31 | 102.52 | 8.5 |

The bentonite system changes from good dispersion stability to general stability, and the agglomeration ability of composite additives is enhanced;

Compared with bentonite, the physical properties of the compound additive are greatly improved;

The new molecular structure of the composite additive is constructed in the form of organic functional groups embedded in the molecular layer of montmorillonite.

Related Products

Welcome your message consultation